The folding tent of the future:

Research and development at Pro-Tent

Products are being continuously improved

Pro-Tent follows a simple principle - perfection! Nowhere is this more noticeable and visible than in product development. Already the company's founder Heinz Stöckler was a successful tinkerer. Among many other inventions, the first aluminium folding frame also came from his sketchpad. While the first folding tent was created on a drawing board back then, the developers at Pro Tent now work with modern CAD programmes.

Products are continuously being developed and advanced

Today, the market for classic folding tents has hundreds of suppliers. The majority of systems are cheap copies, hundreds of thousands of which are manufactured in Asia. Pro-Tent, on the other hand, has continuously developed its product and driven forward technical advances and improvements with passion and a spirit of innovation. This has resulted in many unique products that set standards in the industry. In addition, Pro-Tent is the only folding tent manufacturer that focuses on the construction of the frames. Today, the Pro-Tent folding frame is not only the basis for a folding tent, but also for an exhibition stand and a room-in-room system.

Sustainable and social product development

30 years ago, Pro Tent concentrated exclusively on functionality, but today our developers think much further ahead. For example, we try to make the development of our products as sustainable as possible, taking into account ecological, economic and social aspects. When selecting raw materials, we attach importance to ensuring that the components can be recycled in the best possible way after the longest possible life cycle or that only low emissions are produced during disposal. That is why, for example, we deliberately do not use a PVC coating on the folding tent fabrics and instead rely on a PU coating.

Long life as a central element of development

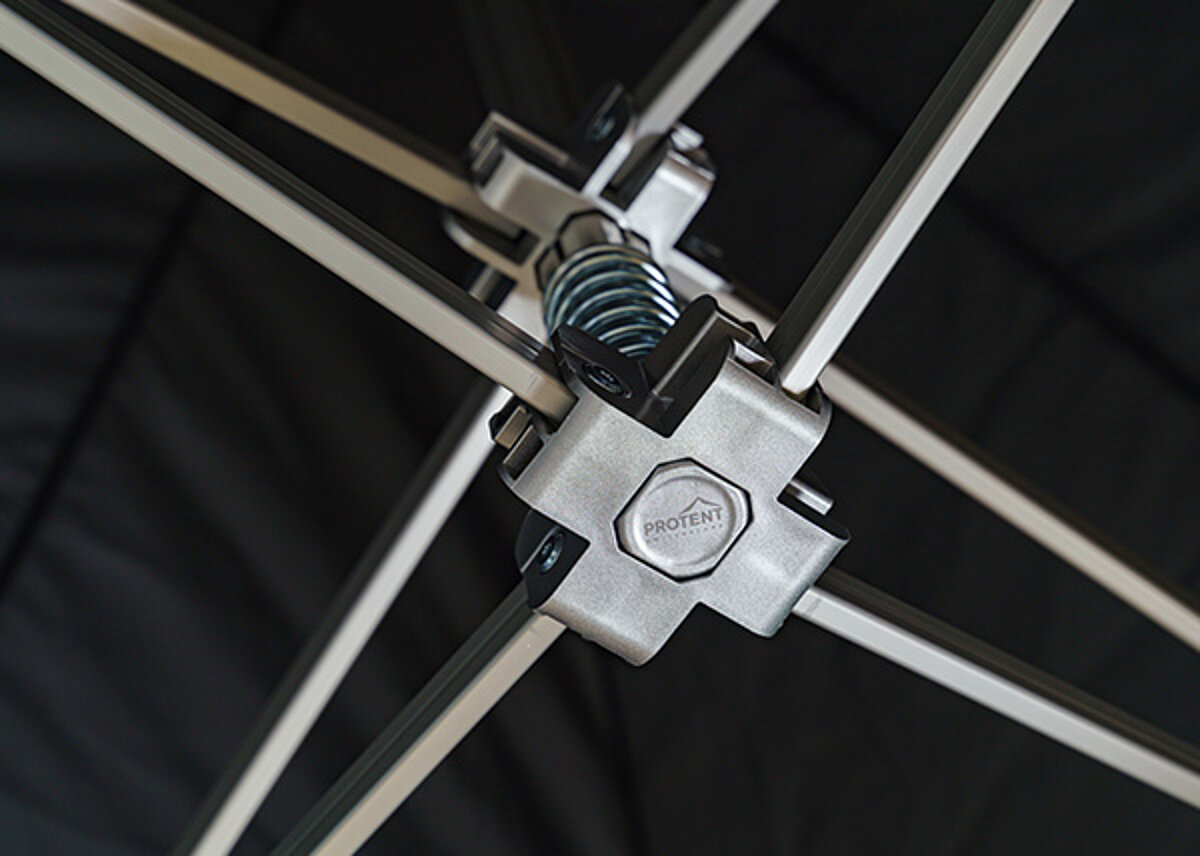

A long service life is just as important. With most folding tents, the aluminium profiles, which are expensive and can only be produced using a lot of energy, are the biggest weak point. Pro Tent therefore uses fibreglass-reinforced plastics instead of metal connectors. These are much lighter than metal connectors with similar strength and can be matched exactly to the aluminium profiles. This means that we use complex load case calculations to analyse up to what point an aluminium profile can withstand the acting load. With this knowledge, the predetermined breaking points in the lower-cost and easy-to-replace plastic parts are calculated. In practice, this saves the customer a lot of money in the event of damage and the parts can be replaced quickly and easily.

Focussing on customer needs

As a customer-oriented company, the suggestions and wishes of our customers flow into product development just as much as our own experience and ideas. A customer once remarked that you can see the quality and attention to detail at Pro Tent just by looking at the packaging concept. We say: We just like to think things through.